Our services

From consulting and strategy development to implementation and support, our comprehensive services can help your business thrive.

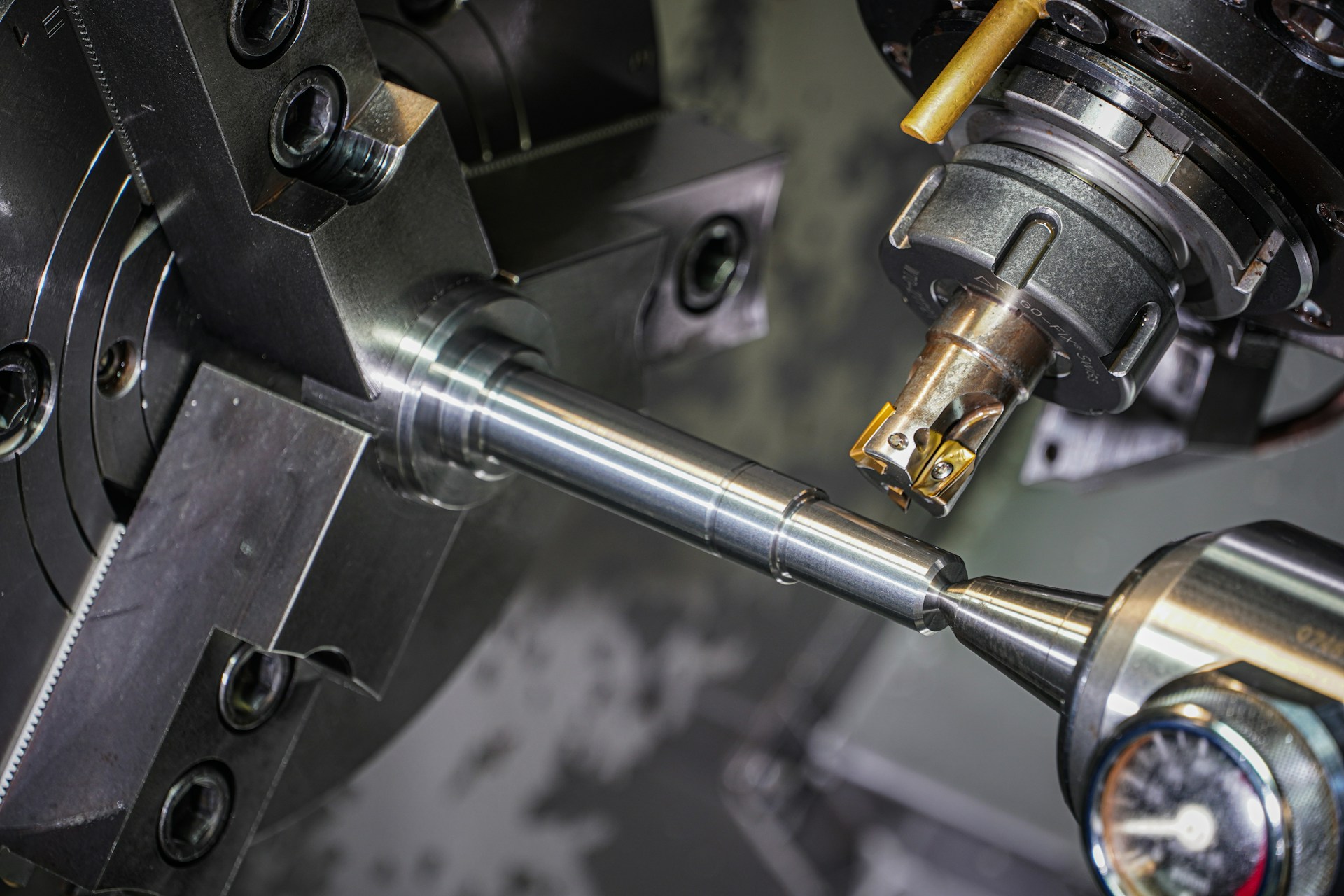

Paramjeet Auto Industries could offer, CNC and VMC (Vertical Machining Center) machining:

High-Volume Precision Machining:

CNC Milling: High-speed and high-precision milling for various parts with complex geometries.

CNC Turning: Efficient turning operations for producing cylindrical parts in large quantities.

VMC Machining: Utilization of vertical machining centers for precise and efficient production of parts.

Custom Manufacturing Solutions:

Large-Scale Production Runs: Capable of handling high-volume production orders up to 700,000 parts per month.

Custom Part Fabrication: Tailored solutions for custom parts based on client specifications and designs.

Material Versatility:

Metal Machining: Processing of various metals, including aluminum, steel, stainless steel, brass, and titanium.

Exotic Materials: Capability to work with advanced and high-performance materials.

Advanced Engineering and Design Support:

CAD/CAM Integration: Advanced design and manufacturing support with integrated CAD/CAM software.

Design for Manufacturability: Consultation on optimizing designs for efficient and cost-effective manufacturing.

Quality Assurance and Control:

In-House Inspection: Comprehensive quality control with precision measurement tools and equipment.

ISO Certifications: Adherence to industry standards and certifications for quality and reliability.

Statistical Process Control: Implementing quality monitoring techniques to ensure consistency and precision.

Value-Added Services:

Post-Machining Processes: Secondary operations such as deburring, surface finishing, coating, and polishing.

Assembly and Sub-Assembly: Assembly of parts or sub-components as required by clients.

Packaging and Logistics: Custom packaging solutions and efficient logistics to meet delivery requirements.

Maintenance and Technical Support:

Routine Maintenance: Scheduled maintenance services for CNC and VMC machinery to ensure optimal performance.

Technical Support: On-demand technical support for troubleshooting and machine optimization.

Efficient Production Management:

Lean Manufacturing: Implementation of lean principles to enhance production efficiency and reduce waste.

Flexible Scheduling: Adaptable production scheduling to meet varying client demands and deadlines.

Consultation and Training Services:

Machining Consultation: Expert advice on material selection, process improvements, and design optimization.

Operator Training: Training programs for CNC and VMC machine operators to ensure proficient and safe machine use.

Environmental and Safety Compliance:

Sustainable Practices: Adoption of eco-friendly practices and waste management systems.

Safety Standards: Compliance with safety regulations to ensure a safe working environment.